Get Your Workshop Ready for Winter

The clocks have gone back and the nights are getting darker, but for those running workshops the biggest hazard caused by winter’s arrival is the cold.

Here is PCL’s guide to preparing your workshop and equipment for falling temperatures.

Thickening oil

Problem: Lower temperatures can interfere with oil viscosity, causing it to thicken. For those relying on an oil bath-design rotary screw compressor to power air tools and inflate tyres, thickening oil can be catastrophic. The motor will struggle to operate with the lack of lubrication and drag caused by the thicker oil, increasing the current and tripping breakers. In the short term, you could end up with a system shut-down, leaving you without a compressed air supply. In the long-term it can cause permanent damage to the motor.

Solution: Use the correct viscosity synthetic oil.

PCL's range of air tool and compressor oil

Hose cracks and leaks

Problem: When rubber and other elastomeric sealing materials get too cold they lose elasticity. This makes hoses brittle and easier to crack and seals more prone to leaks.

Solution: Avoid choosing a hose made from rubber. Instead choose a rubber blend hose, or one made from synthetic material such as PVC. We recommend High Visibility PVC Air Hose which can help reduce trip hazard potential in dark or poorly lit work areas - ideal for mobile service vehicles on dark nights, providing extra safety.

PCL's range of air hoses

|

Available in popular cut lengths with fittings |

High visibility version now available |

Tyre hazards

We all know that snow and ice can making driving dangerous, so adjust our driving accordingly. Not everyone is aware though that cold and damp roads can hugely affect tyre performance. The roads look no different to wet conditions when it’s warmer, therefore drivers may not take extra care.

Problem: Temperatures below 7°C cause the tread compound in normal tyres to harden, reducing grip. Some drivers may fit winter tyres to prevent this. However, regardless of whether they change their tyres for winter, all drivers should check tyre condition regularly to ensure maximum safety. Low/illegal tyre tread and inaccurate tyre pressure can affect steering, acceleration and braking, making winter driving extremely hazardous.

Solution: Those running workshops should ensure they have accurate equipment to check and inflate tyres to help keep their customers’ tyres safe and legal.

PCL’s AIRFORCE MK4 Tyre Inflator is a superb handheld option for the busy demands of a modern garage and tyre shop. Delivering enduring accuracy, speed and reliability, The MK4 is easy to use, with a 20% larger screen and clearer to read scale. This high performing linear gauge features a two-stage valve design which ensures enhanced accuracy and longer life compared to competitors’ single-stage mechanisms.

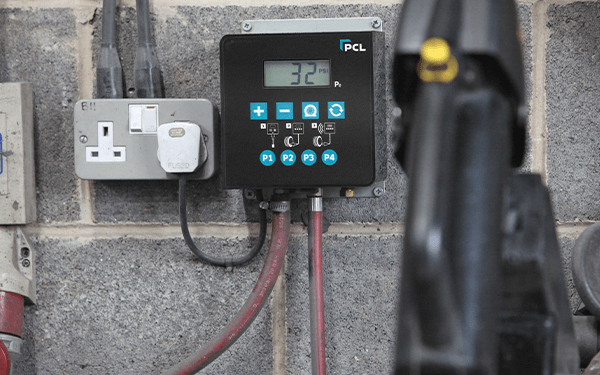

For those requiring a fixed unit, the space-saving, entry level ACCURA QUBE Series II Tyre Inflator is a cost-effective choice for fast and safe digital inflation. The addition of “human-touch” recognition software to the buttons makes this a robust SMART unit that’s speedy and easy to use. All users need to do is pre-set the required pressure, place the connector on the tyre, and let the inbuilt auto-start function do the rest.

If you’re not sure which type of inflator will best suit your workshop, you can read our guide here.

Your workshop will also benefit by taking stock of PCL’s handy range of tyre care tools, including traditional pencil style tyre pressure gauges, DVSA-approved tyre tread depth gauges, and digital tyre pressure and tread depth gauges.

PCL equipment to keep tyres safe and legal

Air Leaks in compressed air systems

Problem: Neglecting leaks on your compressed air system can result in a 20-30% loss of power and air capacity. Therefore, it is vital to find and repair any leaks before winter sets in to make your system both air and watertight. That way you can avoid breakdowns, a reduction in efficiency, and an increased carbon footprint. Just a 2mm hole in your pipe work could cost you over £1,249 each year in wasted energy (BCAS, 2022). You can find out more about this here.

Most often, a leak will come from the connection points, for example the couplings.

Solution: Use high quality, tried and tested equipment that comes with a warranty, such as PCL couplings. PCL’s core lines of “blue-band” couplings – Airflow, Vertex and XF-Euro - are durable, fail-safe and come with a 5-year warranty.

PCL’s core lines of “blue-band” couplings

Condensation in compressed air systems

The amount of water vapour in atmospheric air depends upon the how hot or cold it is. When temperatures rise there will be more water – which is what causes steamy weather in tropical climates. In lower temperatures, water condenses, forming dew when it’s above freezing, and frost when it’s below.

Problem: Condensation corrodes exposed mental, especially inside electrical enclosures, resulting in short circuits. Compressed air systems must be kept clean and dry to ensure continued reliability.

Solution: Install a filter. Where the filter is installed in a hard-to-reach area, a filter with automatic drain is recommended. We offer options with both manual or automatic drains. Check out the PCL Air Treatment series - a range of Filter, Regulator and Lubricators (FRLs) designed for maximum efficiency and performance.

PCL's range of Air Treatment units

Water in compressed air systems

Water, or condensate, is created during air compression. As atmospheric air is sucked into the compressor, the water in it is squeezed out by the pressure and released into a condensate trap. To remove any additional moisture, systems will usually incorporate a dryer. It is vital to keep your compressor’s distribution system free of water to keep it working properly.

Problem: Clogged drains and backed-up water can stop your air compressor from running efficiently, and in the worst-case scenario cause damage and breakdowns.

Solution: Carry out essential checks and maintenance, especially if you’re turning it off for winter or closing down for Christmas. Essential work includes:

- Draining unused lines. Ensure all water is drained out of the drain lines to stop them freezing.

- Cleaning drains, valves and separators. Clogged drains will stop your compressor from running efficiently, and any water backing up as a result can turn into ice, with moisture damaging valves and separators.

- Checking filters. Clogged filters increase the risk of pressure drop and contamination and allow water and ice to collect.

According to the Department for Business, Energy and Industrial Strategy, compressed air systems are responsible for around 10% of all industrial electrical consumption, resulting in CO2 emissions of 3,100 kt/year. A neglected compressor could land you with a big utility bill as well as profits lost through downtime.

Cold hands and handles

Cold hands and tools can be an uncomfortable combination, especially if you’re working outside or late into the evening.

Problem: If you’re using air tools or blowguns with metal handles this can reduce user comfort, especially with the addition of chilly compressed air. This can become even more problematic if the task in hand is repetitive and time-consuming.

Solution: If you’re using an everyday air tool, such as those in our PRO range or PCL Metal Blowgun, you could use safety gloves for extra comfort. That will allow you to still take advantage of our high performance but competitively-priced selection of PRO products, which are built to withstand rigorous use in the heaviest of workshop and tyre environments.

Ergo Extreme Blowgun with non-slip rubber handle

Or you could choose a PRESTIGE air tool or ERGO Extreme Blowgun - both of which feature a non-slip soft grip rubber handle. This makes them safe and comfortable to use, whilst providing protection against the cold compressed air. In addition, their ergonomic handle design and lightweight body have been developed to reduce fatigue during prolonged periods of usage.

You can see PCL’s full range of robust and handy air tools, designed to tackle any job at any scale, here. If you’re not sure whether to choose PRO or PRESTIGE, you can find out more about the differences here.

Preparing your workshop for winter by following the simple steps above can help get you through the winter with a reduced risk of breakdowns, whilst increasing efficiency and making much-needed energy savings.