How to choose the right compressed air hose for your application

To make the most out of your pneumatic tools, choosing a quality hose is essential to ensure stable air pressure.

Here is a quick and easy guide on the factors you should consider in order to select the right air hose for your application.

Hose length

When selecting an air hose, you should always consider your application and total distance between the compressor system and where you will be using the air tool and how much movement you will need.

To minimise the risk of a pressure drop, you should never use a longer hose than you need. For example, a carpenter working at the same bench all day using a nail gun will only need a small hose length, whereas a tyre fitter who needs to manoeuvre around large vehicles while using an impact wrench, will require a longer hose length.

We recommend that you use a longer air hose rather than an extension lead with an air compressor, as the voltage drop from using an extension lead can cause the motor to overheat which will eventually lead to the compressor motor burning out.

Hose Size

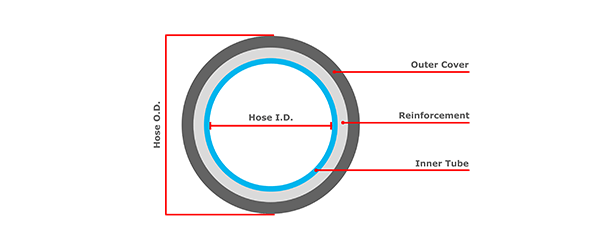

Hose specifications usually list both the hose Outer Diameter (O.D.) and the Internal Diameter (I.D.). However, hose size refers to the hose I.D., rather than the hose O.D.

The hose O.D will depend on the thickness of the hose and reinforcement layer, while the hose I.D. determines the capacity of air the hose can carry.

Common hose sizes are 7 mm (1/4 in), 8 mm (5/16 in), 10 mm (3/8 in) and 13 mm (1/2 in). To maintain adequate airflow, you must ensure that the Hose I.D is not too small for the tools CFM requirements as this will affect your tools performance.

Air tools that require a lower 1-3 CFM such as a nail gun, usually work well with a 7mm hose. Air tools that require a larger CFM such as an ½” impact wrench will require a minimum of 10mm hose to run at full capacity.

The air tool manufacturer will usually list the minimum hose size on the tool’s specification.

Maximum working pressure

This will depend on the maximum pressure relevant to your air supply. The maximum working pressure of the hose must be equal or greater.

The hose specification may also list the burst pressure, which is the maximum pressure before the hose will rupture. Most hoses in the PCL range offer a 3:1 Safety Factor, this means if the hose is rated at 21 bar / 300 psi working pressure, the burst pressure will be 63 bar / 900 psi. You should not use the burst pressure as an indication that the hose can be used above the maximum working pressure, the burst pressure is for manufacturing test purposes only.

Type of hose (Standard or Coiled)

There are two types of hoses, Standard or Coiled, your application will determine which type of hose you require.

The material of the hose will affect the flexibility, weight, longevity, and performance therefore you will also need to ensure that the material is suitable for your application.

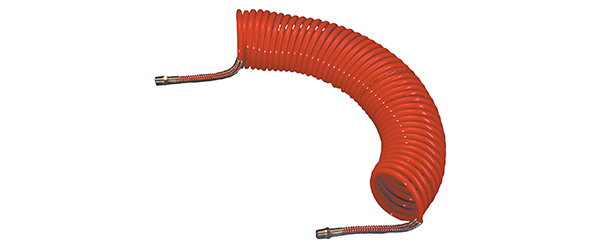

Coiled Air Hoses

Available in Polyurethane or Nylon, PCL’s coiled hoses are ideal for applications where space is tight. The coils are tensile and have a memory so when you let go of the hose, it shrinks back for easy storage, and leaves the work area clear of entanglements and trip hazards. Many factories use coiled hoses as they spring out of the way when they are not in use.

What application is Polyurethane (PU) hose suitable for?

PCL’s range of durable and hardwearing Polyurethane (PU) hoses are ideal for applications that require a tighter bend radius, such as in robotics and pneumatic control machinery.

PU hoses have an excellent resistance to abrasion from fuel, oils and abrasion and is commonly used in medium pressure applications.

What application is Nylon hose suitable for?

Nylon also has excellent resistance from fuels, oils and abrasion, however offers greater heat and chemical resistance and supports a high working pressure than Polyurethane (PU), therefore is recommended for higher pressure applications.

Standard Air Hoses

PCL’s range of standard hoses lie flat, without bends or coils, some prefer standard air hoses because they don’t like the resistance in coiled hoses. You can loosely wrap the hose into loops for storage. Alternatively, you can mount them in a hose reel that can be wound up with a crank handle and mounted on a wall.

What application is PCL’s Superflex Air Hose suitable for?

PCL’s SuperFlex hose has been designed to be extremely flexible and hard-wearing. The material on the inside of the hose is made from a special PVC nitrile grade, which is twice the strength of normal flexible PVC while still being soft, this offers great elasticity without damage and excellent kink recovery – which results in minimum air flow loss.

The material on the outside of the hose is made from the same material used on window gaskets in double glazing and is approved BS EN 12365-1 (building standard for weather strips on doors and windows), therefore the hose offers excellent weathering properties, excellent oil resistance and soft touch for excellent handling and increased user comfort.

The combination of these materials makes the SuperFlex hose suitable for most applications. The SuperFlex hose has excellent low temperature performance down to -40oC, however it is recommended to avoid high temperatures as the hose may become too soft.

What application is TPE / PVC Air Hose suitable for?

PCL also offers a range of hoses made from a high-performance TPE compound, these hoses look and feel like rubber however are lighter in weight. This ergonomically friendly product is a good purpose all round hose, and works up to 20 bar, rather than 14 bar compared to the SuperFlex Hose.

PCL also offers a high visibility yellow PVC hose, ideal for dark or poorly lit work areas, providing extra safety.

Nylon Tubing

PCL also offers flexible nylon tubing. Manufactured from high quality nylon granules, this tubing is ideal for use with push-in fittings and for a wide range of industrial applications.

Hose End Fittings

Ensuring that you select the right fittings and connectors for your system is critical to achieve a good seal and optimum air tool performance.

For your convenience PCL also has a range of hose assemblies, complete with couplings and adaptors – investing in a PCL air tool hose saves the time and expense of buying expensive crimping equipment – you can simply plug in and go.

|

|

|

Explore the full range of Air Hoses with Fittings

Replacing your hose

Hoses naturally wear over time, the service life depends on several factors including the hose’s quality, material, frequency of use and maintenance. It is important to inspect your hose and fittings for damage regularly and before use. If there is a defect, you will need to replace the hose.