Why use a Safety Coupling or Adaptor?

Coupling connections are subject to Health and Safety regulations, due to the dangers associated with hose whip. The Health & Safety Guide HSG 39 recommends that for all hoses above 10 mm bore, more than 10 m long or subject to a pressure exceeding 7 bar, the connector should have a self-venting coupling, alternatively an adaptor with a controlled venting action should be used.

The use of a self-vent safety coupling ensures that pressure in the circuit is reduced to a safe level before the coupling and adaptor can be disconnected, this prevents accidental tool operation and uncontrolled whipping of the hose. Not only does this enhance workplace safety by protecting users from the severe injuries caused by hose whip, but companies can benefit from increased uptime and fewer repair or replacement expenses.

Safety Tip: When using air tools, it’s also important to remember to use an anti-whip hose to enhance safety and prolong the life of your couplings. Read more.

Example of hose whip using a non-safety coupling

How do PCL's Safety Couplings work?

PCL offers two styles of safety couplings to suit user preference - the new style push button and the traditional sliding sleeve operation – both of which conform to compressed air Health & Safety Guide HS(G)39.

| Push Button Operation | Sliding Sleeve Operation | |

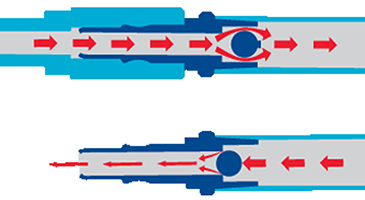

Both feature a two-stage self-venting release. This means that when the user first moves the coupling sleeve back towards the threaded end of the coupling or pushes the button, the coupling releases the downstream pressure whilst the adaptor is held safely in position. Once the pressure is released, the user will then need to move the sleeve back into the original place or press the button a second time to release the adaptor.

|

Demonstration of the UK Standard Push Button Safety Coupling |

Demonstration of the Safeflow Safety Coupling |

PCL’s range of Safety Couplings are available in different thread types and sizes. Unsure what thread size coupling you have? See our handy guide.

What's the difference between PCL's Standard and XF-Euro Safety Couplings?

|

UK Standard Push Button Safety Coupling with UK Standard Adaptor |

PCL’s Standard and XF-Euro Safety couplings are compatible with different adaptor profiles, PCL’s UK Standard Push Button and Safeflow Safety Couplings are compatible with PCL’s Standard Adaptors and come with a 5 year warranty, whereas XF-Euro Safety Couplings are compatible with PCL’s XF-Euro Adaptors. The XF-Euro Safety Coupling has a larger nominal bore therefore is ideal for higher flow applications.

See our handy guide to find out more about how to choose the correct adaptor profile for your coupling.

How do PCL's Safety Adaptors work?

PCL’s Safety Adaptors feature a choke which allows air to vent slowly when disconnected from coupling preventing hose whip.

PCL Safety Adaptor Diagram

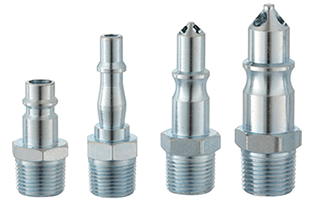

PCL’s range of safety adaptors

| Part Number | Thread Type | Thread Size | For use with |

| ACA9101 | Male | R1/4 | Airflow/Vertex Coupling |

| AA7103/STY | Male | R3/8 | XF-Euro Coupling |

| ACA9201 | Male | R3/8 | 60 Series Coupling |

| ACA9301 | Male | R1/2 | 100 Series Coupling |

| AA5103/STY | Male | G3/8 | Instantair Coupling |