The evolution of the Standard PCL Coupling Series

Over three quarters of a century since PCL manufactured and patented the first ever “Made in Sheffield” coupling, the Standard Air Line Coupling, now known as the Airflow Coupling has become an essential piece of kit in workshops all over the world.

The standard range has been developed over the years and now features the Airflow, Vertex, Non-corrodible and Safeflow, all suitable for use with PCL’s UK Standard Adaptor profile.

After nearly 80 years of design enhancements; this range is still manufactured in Sheffield to the highest standards.

1940s

The journey begins in the early 1940s when PCL started to manufacture the Standard Air line Coupling and Adaptor at the Brown Steet Workshop in Sheffield, before moving its operations to the Eyre Street factory in 1946.

The patented coupling was described as light in weight (2 kgs) yet sturdily built for long life. Though today this coupling weighs significantly less (0.11 kgs), it is still built with durability in mind.

|

Here's a blast from the past... |

|

|

|

One of PCL's partner engineers discovered original PCL couplings on Britain’s only remaining A Class Submarine HMS Alliance, from WWII 1945 in Gosport, when he visited the Royal Navy Submarine Museum. |

1950s

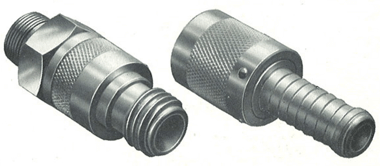

The Heavy Duty Coupling was introduced. This featured ‘ a shockless valve action’ meaning the back pressure was slowly and automatically released on disengaging the threaded end, thus elimainting the dangers of built up pressure.

PCL's Heavy Duty Coupling from the 1957 Catalogue

1960s

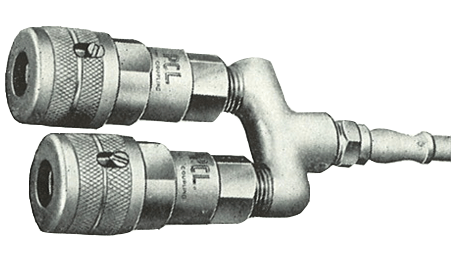

In the early 1960s, PCL had extended the range to include a Twin Standard Coupling, this allowed two operating points off one main air supply outlet.

PCL's Twin Standard Coupling from the 1963 Catalogue

By the end of the decade, the range included various coupling profiles such as 60, M100 and WEE Series to cater for different industries and applications such as industrial where greater flow rate was required, medical and dentistry.

1970s

In the 1970s, over 30 years since its launch, the Standard Coupling was more popular than ever and was used in many interesting applications, some of which are explored below.

|

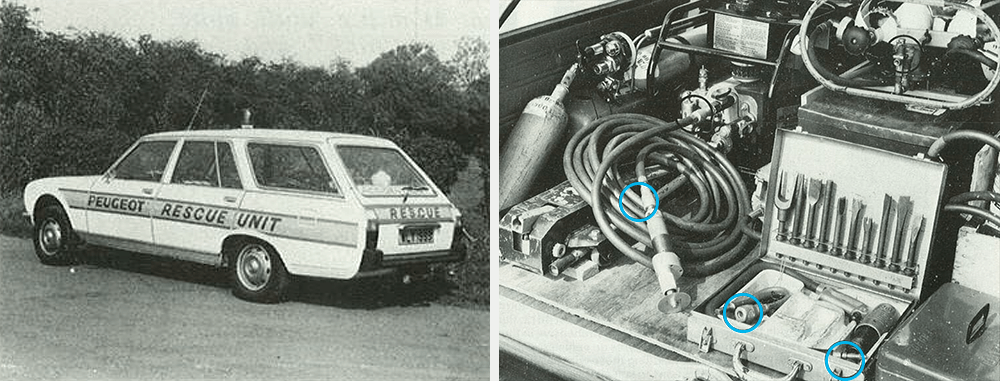

PCL to the rescue |

|

PCL’s Standard Coupling was and still is referred to as the ‘Quick release coupling’, that’s why it was a popular choice for rescue vehicles. |

|

Commando fire trucks Standard PCL couplings were fitted to a Commando fire fighting vehicle. The vehicle made by Carmichael and sons (Worcester Ltd) and is used in emergency situations where vital second couts, and it is essential that the air line couplings for the air operated cutting tools had the quiest and easiest action possible.

|

|

Grand Prix Rescue teams One of our customers in the 1970s - Mr Paddy Kenshole - devoted much of his spare time to voluantarily run a rescue team at various Grand Prix circuits throughout the country. The crew used a Peugeot 504 estate to carry 750 kg of special rescue equipment for fighting fires, breathing apparatus, special suits and a range of air tools, all powered by a compressor. The compressor, emergency bottles of compressed air and tools all used PCL Standard Couplings and Adaptors. Mr Kenshole insisted on using PCL couplings as “They work every time, even when your hands are cold, they give an excellent seal and they’re reliable.” (PCL News, 1979).

|

1980s

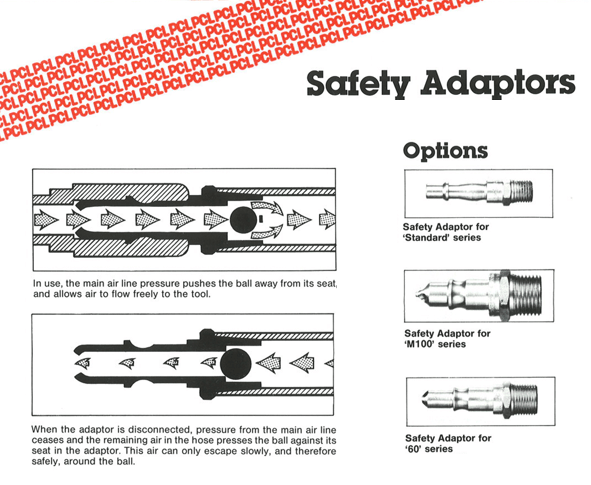

PCL introduced the Safety Adaptor range

In the 1970s, the UKs Health and Safety at work act and similar legislation in many other countries led to a much greater awareness of safety procedures throughout industry as a result there was a significant demand for products which incorporated safety features. To cater for this demand, in 1980 PCL launched its range of safety adaptors for use with the Standard, 60 and M100 couplings.

PCL's Safety Adaptors range (1980)

To find out more about why you should use a Safety Coupling or Adaptor and how they work, read our handy guide.

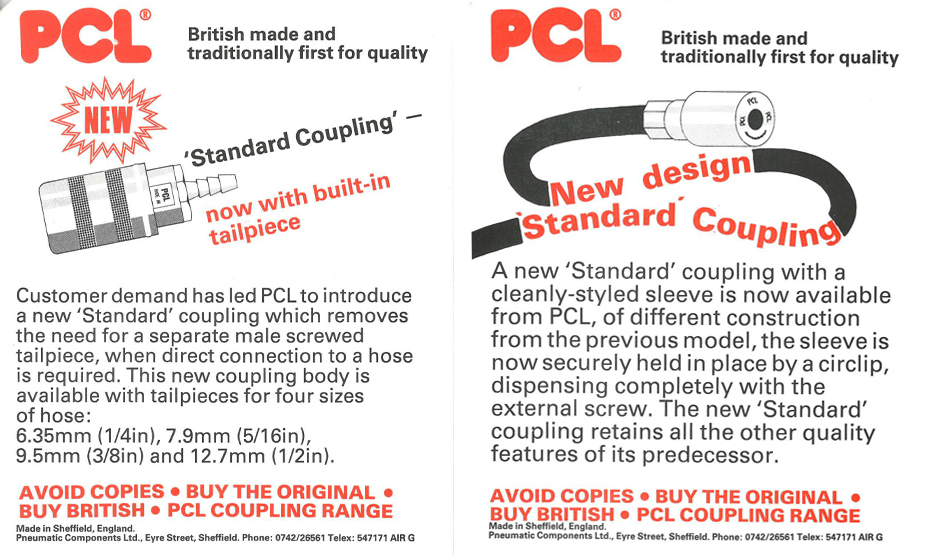

The Standard Coupling had a facelift

Over 40 years after its launch, the Standard coupling was given a face lift to feature a cleanly-styled sleeve which was securely held in place by a circlip, dispensing completely with the external screw, while it retained all the other reliable qualities of its predecessor.

After high customer demand, PCL also added the Standard coupling with built-in tailpiece, this removed the need for a separate male screwed tailpiece when direct connection to a hose was required.

PCL's Standard Coupling in 1986

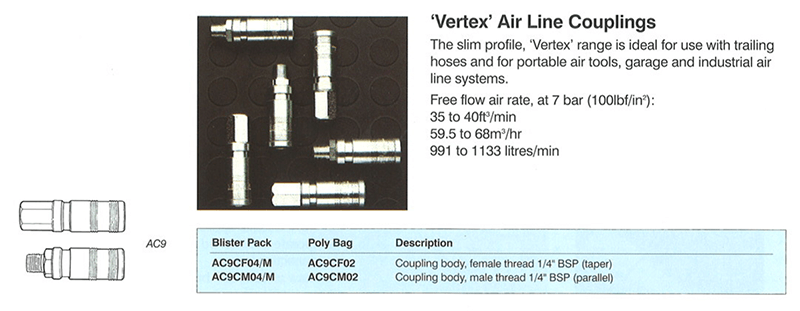

The Vertex Trailing Hose Coupling was launched

In the same year, the Vertex trailing hose coupling was launched. Featuring a double action mechanism to protect against accidental disconnection, the Vertex was designed for use with portable air tools, garage and industrial air line systems.

Vertex Couplings - Extract from PCL's 1995 Catalogue

1990s

Airflow and Vertex range

In 1995, new couplings branded Airflow (previously Standard Coupling) and Vertex were introduced.

Want to learn more about the difference between the Airflow (previously standard) and the Vertex coupling. Read our handy guide.

|

Airflow Series (1995) |

Vertex Series (1995) |

European profiles were added to the range

The following year, a new range of high-flow industrial couplings branded XF and ZF were released. These matched the common European styles of pneumatic quick-connect couplings.

|

Euro Coupling and Adaptor (1996) |

ZF Coupling and Adaptor (1996) |

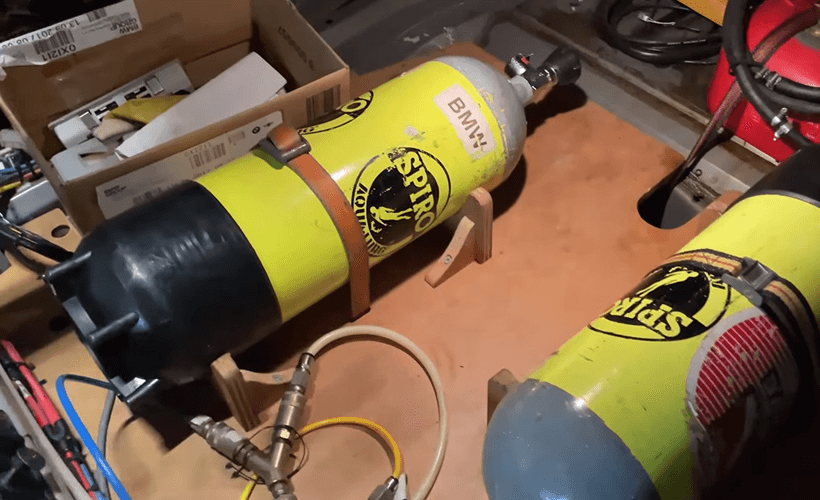

PCL's Airflow selected for Bond's Secret Service Missions

One of our biggest claims to fame is that PCL Airflow Couplings were used on the tanks that powered the gadgets on James Bond’s 1997 BMW 750iL in Tomorrow Never Dies. You can see them in Supercar Blondie’s video at the 3-minute mark.

PCL's Airflow Twin Couplings installed in James Bond's 1997 BMW 750iL as seen in Supercar Blondie’s video

2000s

Non-corrodible Series

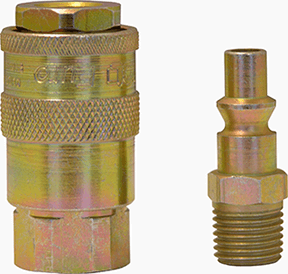

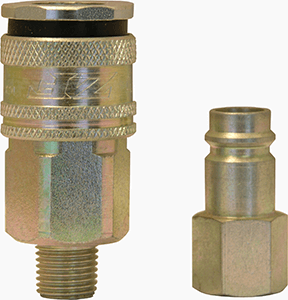

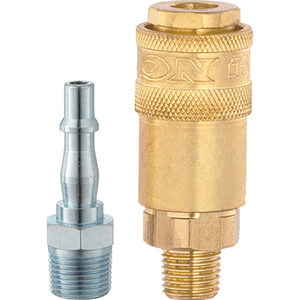

In the early 2000s, the non-corrodible brass range was introduced. This coupling was designed for specialist applications such as breathing air, non-spark, damp or high condensation environments and can be used outdoors.

Non-Corrodible Coupling with Standard Adaptor

Safeflow Safety Series

In 2006, PCL’s Safeflow standard safety coupling was patented and launched. This safety range offers a two-stage self-venting release which completely eliminates the dangers of hose whip.

To find out more about why you should use a Safety Coupling or Adaptor and how they work, read our handy guide.

Promotional Flyer for the launch of the Safeflow Safety Series (2006)

2010s

PCL extends Interchange range

By 2010, the InstantAir, Mini, ISO B 12, KF and A Style Series were introduced to accommodate different markets.

2020s

75th anniversary of the invention

To celebrate 75 years since the Standard Couplings invention, PCL revealed the latest generation of couplings – Airflow, Vertex and XF-Euro - featuring a distinctive blue band to define them as genuine “Made in Sheffield” products. Their material thickness was increased to neatly house the stylish blue band, providing extra durability. These three key ranges also now come with a 5-year warranty, as does the industry-proven Safeflow Safety Coupling, which features a blue sticker as the PCL mark of authenticity.

These couplings are now date-stamped to increase traceability, performance and maintenance, so customers should always check for this badge of honour to be sure of coupling with confidence.

Spotted in Edd China’s Workshop Diaries EP10

|

|

Do you have a PCL product, old or new? We’d love to see it! Tag us on Instagram @pclairtechnology.